Spot Face Cutter: Difference between revisions

From DT Online

mNo edit summary |

Added Template |

||

| Line 1: | Line 1: | ||

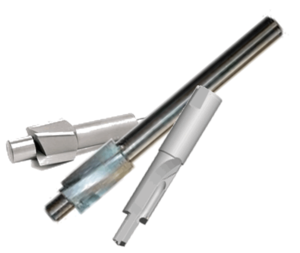

[[File:SpotFaceCutters.png| | [[File:SpotFaceCutters.png|300px|right]] | ||

| Line 7: | Line 7: | ||

This is usuallly a precision engineering operation requiring the use of a '''[[Drill Press]]''', '''[[Centre Lathe|Lathe]]''' or '''[[Milling Machine]]'''. The '''Spotfacing Cutters''' are not really suitable for use with '''[[Portable Electric Drills]]''' | This is usuallly a precision engineering operation requiring the use of a '''[[Drill Press]]''', '''[[Centre Lathe|Lathe]]''' or '''[[Milling Machine]]'''. The '''Spotfacing Cutters''' are not really suitable for use with '''[[Portable Electric Drills]]''' | ||

{{Spot Face Cutter Buyers Guide}} | |||

[[Category:Drilling and Boring]] | [[Category:Drilling and Boring]] | ||

Revision as of 19:32, 15 May 2016

Spotfacing can be neccessary to smooth the rough surface of a casting, for example, around a drilled hole such that a nut, bolt or washer can be more evenly seated.

This is usuallly a precision engineering operation requiring the use of a Drill Press, Lathe or Milling Machine. The Spotfacing Cutters are not really suitable for use with Portable Electric Drills