Hand Drill Stand Project: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| Line 19: | Line 19: | ||

* Measure and examine commonly available '''[[Hand Drill|Hand Drills]]'''. | * Measure and examine commonly available '''[[Hand Drill|Hand Drills]]'''. | ||

* Find out about the '''[[:Category:D&T Resources in Primary Schools|D&T Resources]]''' used in primary schools. | |||

* Visit local primary schools and discuss the problem of drilling holes '''[[Squareness|Square]]''' into sheet materials. | * Visit local primary schools and discuss the problem of drilling holes '''[[Squareness|Square]]''' into sheet materials. | ||

* Observe young children drilling small holes in sheet materials. | * Observe young children drilling small holes in sheet materials. | ||

Latest revision as of 09:20, 10 February 2017

Design Brief

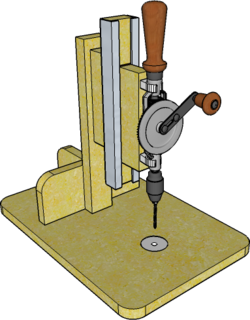

Young children may have difficulty drilling holes which are truly Square to the surface (e.g. of a disc to make a wheel). A simple Jig can be made which supports a Hand Drill within a sliding frame to assist. In use, one child operates the drill and another holds the work-piece to be drilled.

Materials Available

- All materials and sections commonly available in a secondary school D&T Department

- Clips and fittings to hold the hand drill in position (e.g. plumbers' pipe clips)

- Additional components as researched and identified (e.g. telescopic drawer slides)

Considerations/Research

- Measure and examine commonly available Hand Drills.

- Find out about the D&T Resources used in primary schools.

- Visit local primary schools and discuss the problem of drilling holes Square into sheet materials.

- Observe young children drilling small holes in sheet materials.

- Find out about Linkages which may provide a suitable parallel motion (e.g. James Watt Parallel Motion Linkage).

- Research Wood Joints as possible methods of creating the main structure.

- Research components available which may assist.

Ideas

- Try different Wood Joints to create a main structure

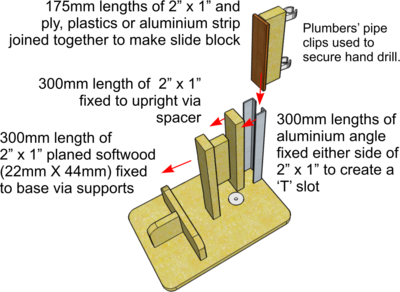

- Explore how a slide can be built up using standard sections

- Consider using components such as a 250mm drawer slide to guide the vertical motion.

Design Development and Construction

- One solution with some typical dimensions is shown for guidance.

- Consider other ways of supporting the vertical sliding block

- Consider how the vertical sliding block can be fabricated - or substituted by a ready made slide.

- Think about how the vertical motion can be provided by linkages rather than a slide.

Testing and Evaluation

- Re-visit a local primary school and observe young children using your Hand Drill Stand

- Does it help them drill holes Square to the surface of sheet materials

- Are young children able to use it?

- Do young children enjoy using it?

- How much would it cost to manufacture?

Further Work

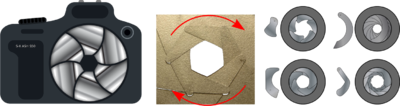

- Consider how to design and make a simple Jig to hold the work whilst drilling discs to make wheels - ideally one which 'self-centres' the discs.

- Research Iris Diaphram, as used in camera lens to change the aperture size, as a possible approach to a solution.

|

|

|

|

|

|

| Pistol Grip Hand Drill |

Double Pinion Handdrill |

Pin Vise Model Hand Drill |

HSS 1-6mm Twist Drill Set |

Bow Drill |

Archimedean Spriral Push Drill |