Timber Defects

From DT Online

Introduction

A Defect is taken to be any irregularity occuring in or on the timber which may lower its strength, durability, utility value or diminish its appearance. Defects may be 'natural' which occur whilst the tree is growing, or 'artificial' as a result of poor conversion, seasoning or handling after felling.

Knots

A most commonly observed defect in timber are Knots. These occur where branches have grown out of the tree trunk. They are more common in some timbers (e.g. Pine) than others. ‘Live Knots’ are fully integrated with the surrounding timber. They may reduce strength and increase difficulty working the timber but are mainly a visual defect - indeed, Knotty Pine is used to decorative effect. ‘Dead Knots’ by contrast are not integrated and often surrounded by Bark and may show signs of decay. They are loose and cannot be relied on to stay in place, often dropping out, leaving a hole which needs to be filled.

Shakes and Checks

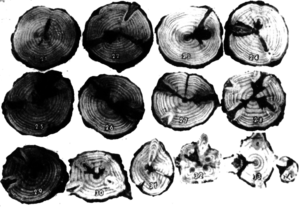

Although the term is often used more widely, a Shake is taken to mean a separation of the Annular Rings (confusingly, this is sometimes referred to as a 'cup shake'). Shakes occur naturally as the tree is growing, especially if in damp conditions. They were once thought to be the result of the tree bending in the wind but research has found that the Clostridium bacterium is the true cause of a Shake.

Checks are a separation of the wood normally occurring across or through the Annular Rings. They are the result outer layers of wood drying out and shrinking around the still moist inner layers. One reason for Converting timber soon after felling is to minimise this problem.

Shrinkage Defects

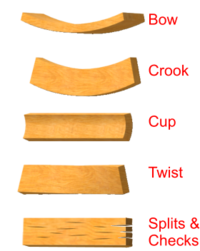

As timber dries out, during Seasoning and afterwards, shrinkage occurs mainly across the Grain with only the slightest movement along the Grain. The amount of Shrinkage across grain varies dependent upon the orientation of the Annular Rings which themselves tend to shorten and straighten out as wood dries. Also, newer wood will tend to shrink more than older wood so the side of a board nearest to the Bark for example, will shrink more than that towards the tree centre. This has various consequences for the way boards of timber react when dried:

- Bow - this is a curve along the face of a board caused by the wood on one face shrinking more than on the face opposite.

- Crook - this is edgewise curving of a board caused by uneven shrinking.

- Cup - 'cupping' is a hollowing of the board throughout its length on its Bark side face: it is for this reason that solid timber window sills, for example, should be positioned 'heart side up'.

- Twist - wood grain is rarely perfectly straight and variations in grain direction and shrinkage over the length of a board can result in one end of a board not being in the same plane as the other; it likely to occur more in thin boards than thicker ones and can be tested using Winding Sticks.

- Splits and Checks - 'splits' tend to occur at the ends of boards and go through from one side to the other; 'checks' are a partial separation of wood fibres across the Annular Rings .

Note: Natural timber continues to swell and shrink as atmospheric conditions and Humidity change. Allowances must be made for this expansion and contraction when designing in solid timber if warping, cracking and splitting is to be avoided.

Infestation

Commonly referred to as Woodworm, timber can be infested with the wood-eating larvae of various species of beetle. Sapwood in particular, and any wood that is in damp and poorly ventilated conditions, is most susceptable to attack. Affected timber can become riddled with small holes to the point where it loses all strength and crumbles.

| Common Furniture Beetle (Anobium punctatum) | B |  |

| House Longhorn Beetle (Hylotrupes bajulus) | B |  |

| Lyctus Beetle (Lyctus brunneus) | B | |

| Death Watch Beetle (Xestobium rufovillosum) | B |  |