Woodscrews and Self-Tappers

From DT Online

Description

Although originally limited to Slot Head (i.e. for Woodscrews) and Square Head (i.e. for Coach Screws), Screws and Bolts of almost all types are now available with a wide variety of head designs and methods of driving them.

The screws listed here are those with a point, rather than a fully parallel shank, and are used mainly for wood, plastics, sheet metal or similar and some building materials.

For details of screws more suitable for Engineering applications (e.g. Set Screws, Cap Screws and Grub Screws, see the page on Nuts, Bolts and Washers

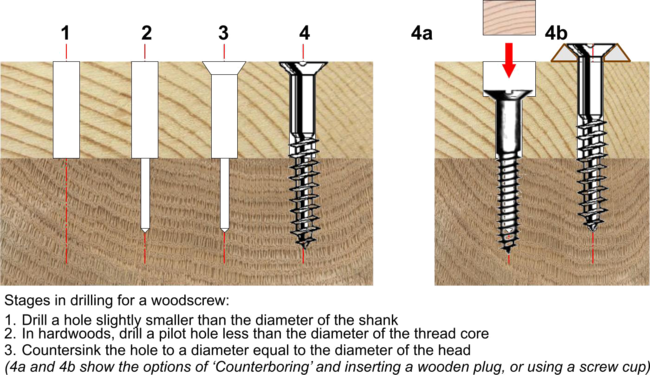

Woodscrews

| Countersunk Head Woodscrews | The most commonly used woodscrew used where the head has to finish flush with the surface. The traditional Slot Head screw is now largely superceded by Philips and Pozidrive head types. They are most commonly available made in Steel, often Electroplated to reduce Corrosion or to improve appearance, but woodscrews made of Brass for example are also common.

Note: Choose a woodscrew twice the length as normal when screwing into End Grain. |

|

| Round Head Woodscrews | These can be used where the material is too thin to countersink or where the screw head is intended to add decoration. They are commonly used to fix metal fittings on to wood - an application for which Black Japanned slot head types were used traditionally.

Note: Whenever Slot Head screws are used, it is good practice to line up all the screw slots to improve the appearance of the finished product. |

|

| Raised Countersunk Woodscrews | These can be used for fixing thicker components on to wood and where strength is required as well as decoration.

Note: Brass woodscrews are sometimes used with Oak because of concerns about the effect of Oak's Tannic Acid on steel ones, but it is advised first to screw in (and then out) a steel screw to avoid the brass screw breaking, since Oak is such a dense Hardwood |

|

| Screw Cups | These can be used when using 'Counter Sunk Head or Raised Head woodscrews with thinner materials or to present a neater finish generally. |  |

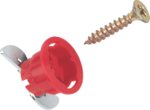

| Plastics Screw Covers | Most commonly used to hide the head of a Counter Sunk woodscrew when assembling products made from laminated Chip Board (e.g. home assembly kitchen cabinets]. |  |

Screws for Metals and Plastics

| Self-Tapping Screw | Used to screw together thin sheet metal, these are made of hardened steel such that they can cut their own threads into a previously drilled hole. |  |

| Tec Screw | Similar to Self-Tapping screws but with the addition of a tip shaped to enable it to drill its own hole to screw into. |  |

| Spire Nut (aka U Nut) | These can be clipped on to thin sheet materials to provide a stronger thread to receive Self-Tapping screws. |  |

Special Purpose Screws

| Mirror Screw | Countersunk Head screws which are drilled and tapped at the top to receive a screw-in dome or cap to provide a decorative finish. |  |

| Coach Screw | Used for larger constructional timber work, these are larger than other screws and with a square or hexagonal head to be driven by a Spanner.

Note: All types of woodscrew can be made easier to screw in if the head is first rubbed with a wax candle or soap or dipped into washing up liquid. |

|

| Screw Hooks and Eyes | Useful as general anchor points (e.g. for garden trellising and picture hanging) the fitting will screw into wood or masonry holes with Rawlplugs fitted. |  |

| Concrete Screw Anchor | Made of hardened steel and able to screw themselves into a previously drilled hole in concrete, brick and blocks as an alternatuve to Rawlbolts. |  |

| Plasterboard Fixing | The aluminium self-drilling fixing can be screwed into plasterboard on hollow walls to provide a moderately strong anchor (plastics versions also available but these need a hole drilling first) |  |

| GripIt Fixing | These fixings can safely carry loads of up to 90kg (180kg max.). They are tapped into a pre-drilled hole and then, using a screwdriver, the two wings at the rear are opened to provide a secure anchor on the back of the plasterboard surface. |  |