Thermoforming Plastics

From DT Online

[[File:]]

Description

The term Thermoforming could be taken literally to include any process which uses heat to create a 3D form - Blacksmithing for example. Throughout DT Online the term is used to include all those processes which employ heat to mould certain plastics.

Synthetic* Plastics are chemically produced from oil and a wide, possibly infinite, variety is possible, but they all fit into one of two groupings:

- Thermoplastics - these can repeatedly be softened by heating and will return to a rigid state when cooled.

- this group includes: Acrylic, Polycarbonate (PC), Polyethylene, and Polypropylene.

- Thermosets - these are initially ‘cured’ (or set), often by mixing with a ‘hardener’ which creates a heat producing (Exothermic) chemical reaction and, once set cannot be softened again by further heating.

- this group includes: Polyester Resin, Epoxy Resin, Bakelite and Melamine.

*Note: Several natural materials may also be classified as Plastics. These include: Cellulose, Horn, Amber, and Shellac.

DT Online includes as Thermoforming all processes in which Thermoplastics are heated to create products with a particular emphasis on methods of moulding flat sheet materials.

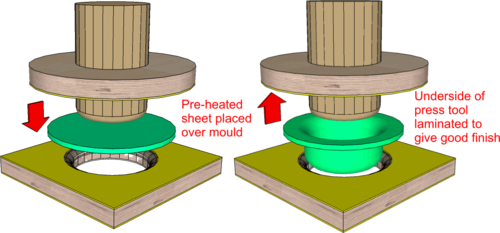

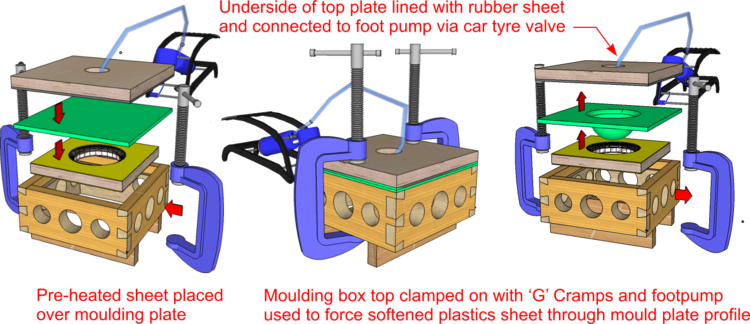

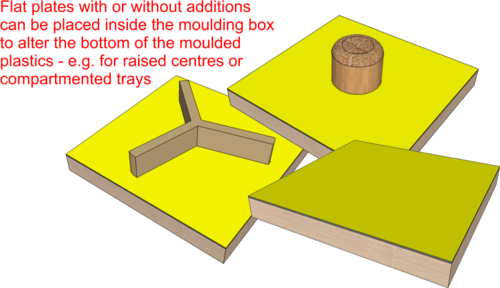

Press Moulding

The sheet of Acrylic can be heated in an oven a between 275°F to 350°F (1350C to 1750C) then placed over a mould shape and pressed into it as shown - the two parts of the mould should be made with an allowance between them to accommodate the thickness of plastics sheet used.

Moulding plates can be Laminated with ‘Formica’ or similar and have well rounded corners to ensure the surface finish of the Acrylic is not unduly marked as pressure is applied.

Small pieces can be heated by careful use of a Hot Air Gun which is continuously moved over the surface until the Acrylic becomes suitably Malleable.

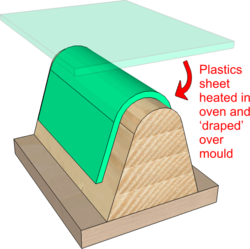

Drape Moulding

The sheet of Acrylic can be heated in an oven as above or small pieces heated with a Hot Air Gun.

Use oven gloves or similar when handling the hot Acrylic sheet and simply ‘drape’ it over a pre-prepared mould.

Minor adjustments can be made throughout using a Hot Air Gun to maintain moulding temperature and an extended moulding time can be achieved if the mould is first pre-heated.

Blow Moulding

Line Bending

As the name implies, a Strip Heater is a heating source which is shielded in such a way that only a narrow strip is exposed. In modern Strip Heaters the heat source is usually a length of Nichrome Wire but older machines may use a Infra-red Element.

A sheet of Acrylic, or similar, can be marked out using a Felt-Tip Pen and the bend or fold line laid across the heating strip untill it softens enough to bend easily by hand to the required angle. Materials thicker than 3mm should be turned regularly to avoid blistering caused by over-heating on one side.

Complex products may be modelled in card first to check which order to complete the bends or folds. Bending Jigs can be made to ensure folds are completed accurately and held in position until the material cools.

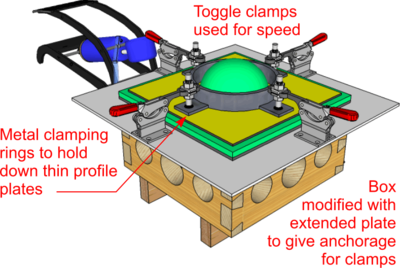

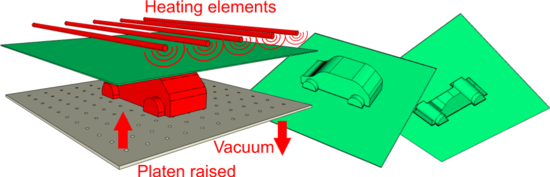

Vacuum Forming

Vacuum Forming is a process in which a sheet of relatively thin Thermoplastics (e.g. 1mm to 3mm thick) is heated, streched over a mould and then sucked down on to it by a vacuum.

The mould can be made by any material which will withstand the heat of the plastic and the force of the vacuum (e.g. wood or plaster). Moulds should be created such that any vertical surfaces have a slight taper or draft to ensure they can be withdrawn after moulding. They should be well finished and brushing on Talcum Powder or using Silicone Spray will aid their release (use only if the inside of the finished moulding is not to be painted - paint does not stick to silicone!). Moulds which have recesses should be made hollow with bleed holes drilled into them to help the vacuum draw the plastic in.

Injection Moulding

Injection Moulding is the most commonly used manufacturing process for the production of a great variety plastic products and components.

In industry, plastics granules are drawn into an Injection Moulder cylinder, or barrel, via a rotating screw to a point where they are heated and melted. The screw then operates as a piston and forces the melted plastic into a mould to create the products as shown:

- Reciprocating screw;

- Hopper;

- Granules;

- Barrel;

- Heaters;

- Mould.

As a consequence, most injection moulded products can be identified by the presence of a small ‘pip’ or sprue where the melted plastics entered the mould.

Extrusion

Extrusion.is an industrial process, usually continuous, which can be likened to squeezing toothpaste out of a tube. Small beads of a Thermoplastics are fed into a hopper from which they feed into the barrel of the Extruder.

The heated Extruder contains a rotating screw which forces the softening plastics through a Die at the end which produces the extruded profile.

The general process of Extrusion can also be used to produce aluminium sections for example, and can be a hot or cold process.for metals such as Aluminium

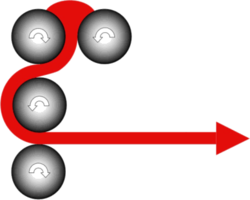

Calendering

Calendering is used to manufacture thin film or sheet in either plastics or paper - or both by laminating films together. The process takes heated and softened plastics and squeezes it through rollers until the required thickness is achieved. It has some superficlal similarities with that used in Steel Rolling Mills and was developed originally for the production of rubber sheet.

Calendars exert immense pressure on the material which results in lower temperatures being needed. This make the process very suitable for materials which may be sensitive to heat damage and for materials such as PVC for which there is some concern regarding fume emissions.

The last set of rollers determines the final thickness of sheet and can also impart a textured surface finish if required.

Rotational Moulding

Rotational Moulding is an industrial process in which a hollow mould is loaded with a measured amount of .Thermoplastics then heated and rotated about two axes such that the plastics forms a coating around the inside of the mould.

Rotation continues throughout both the heating and cooling phases to avoid deformation of the finished product. This makes for a long cycle times but it is still a cost-effective and easy way to produce large hollow pieces such as storage tanks. The moulds for

Rotational Moulding are either fabricated from welded sheet steel or cast and are significantly cheaper than some other types of mould.

Compression Moulding

Compression Moulding is used to create products by placing a measured amount of Thermoset Resin into a heated mould cavity then applying the top of the mould, or plug, with heat and pressure until the resin is cured.

Compression Moulding is a high volume process at a lower cost than Injection Moulding but not as consistent, and it is difficult to control flashing. It is useful also however for moulding composite products such as when Fibreglass (GRP) reinforcement is needed.