Casting: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 15: | Line 15: | ||

It is possible to consider that almost any object can be made by either: | It is possible to consider that almost any object can be made by either: | ||

* '''Reforming Materials''' - e.g. by '''Casting''', '''[[Thermoforming]]''', '''[[Injection Moulding]]''', '''[[:Category:Blacksmithing|Forging]]''', '''[[Laminating]]''' | * '''Reforming Materials''' - e.g. by '''Casting''', '''[[Thermoforming Plastics|Thermoforming]]''', '''[[Injection Moulding]]''', '''[[:Category:Blacksmithing|Forging]]''', '''[[Laminating]]''' | ||

* '''Addition or Fabrication''' - e.g using '''[[:Category:Wood Joints|Wood Joints]]''', '''[[:Category:Adhesives|Adhesives]]''', '''[[:Category:Fixings and Fastenings|Fixings and Fastenings]]''', '''[[:Category:Joining Metal|Welding]]''' | * '''Addition or Fabrication''' - e.g using '''[[:Category:Wood Joints|Wood Joints]]''', '''[[:Category:Adhesives|Adhesives]]''', '''[[:Category:Fixings and Fastenings|Fixings and Fastenings]]''', '''[[:Category:Joining Metal|Welding]]''' | ||

* '''Subtraction''' - or material removal by: [https://en.wikipedia.org/wiki/Cutting '''Cutting'''], [https://en.wikipedia.org/wiki/Carving '''Carving'''], [https://en.wikipedia.org/wiki/Machining '''Machining'''] | * '''Subtraction''' - or material removal by: [https://en.wikipedia.org/wiki/Cutting '''Cutting'''], [https://en.wikipedia.org/wiki/Carving '''Carving'''], [https://en.wikipedia.org/wiki/Machining '''Machining'''] | ||

| Line 26: | Line 26: | ||

[[Category:Skills and Processes]] | [[Category:Skills and Processes]] | ||

[[Category:Heat Area Equipment]] | |||

Latest revision as of 07:33, 18 May 2018

Description

Casting describes the process of pouring a material in liquid form into a mould - e.g.

- Metal Casting - Sand Casting, Die Casting and Lost Foam or Investment Casting

- Resin Casting - such as using clear polyester resin to encapsulate objects

- Plaster Casting - to make 3D copies of animal tracks for example

- Cast Concrete - used to make components for the construction industry for example

Features and Uses

It is possible to consider that almost any object can be made by either:

- Reforming Materials - e.g. by Casting, Thermoforming, Injection Moulding, Forging, Laminating

- Addition or Fabrication - e.g using Wood Joints, Adhesives, Fixings and Fastenings, Welding

- Subtraction - or material removal by: Cutting, Carving, Machining

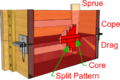

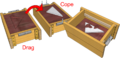

Note: Throughout the articles on Casting, casting in aluminium only is assumed. In the experience of DT Online this is best done such that the mould is in the top box (i.e. Cope) and that a large diameter parallel Runner Sprue is used with no Riser which in effect ‘pressure feeds’ the mould to produce good quality castings. For this reason there may be some mismatch regarding the positions of Cope and Drag as compared with more conventional texts.

Pages in category 'Casting'

The following 6 pages are in this category, out of 6 total.

Media in category 'Casting'

The following 22 files are in this category, out of 22 total.

- CastDTcandleholder.png 214 × 539; 16 KB

- CastDTcandleholder7.png 708 × 768; 51 KB

- CastDTcandleholderMoulding.png 1,015 × 501; 126 KB

- CastDTcandleholderPattern.png 917 × 644; 172 KB

- CastPlaquette1.png 878 × 500; 98 KB

- CastPlaquette2.png 973 × 418; 96 KB

- CastPlaquette3.png 1,002 × 466; 131 KB

- CastPlaquette4.png 995 × 500; 84 KB

- CastPlaquette5.png 998 × 433; 76 KB

- CastPlaquette6.png 898 × 490; 92 KB

- CrucibleFurnace.png 277 × 170; 62 KB

- DTlogo2.png 580 × 411; 87 KB

- GnomonSupport.png 785 × 345; 73 KB

- Machine-576735 640.png 640 × 522; 153 KB

- Matchplate1.png 1,079 × 304; 158 KB

- Matchplate2.png 584 × 511; 331 KB

- Moulding bench M021.png 316 × 334; 121 KB

- MouldingFlasks.png 725 × 484; 64 KB

- Oddside5.png 1,033 × 431; 102 KB

- Oddside6.png 1,046 × 505; 114 KB

- SandCastingCope.png 2,162 × 632; 289 KB

- SandCastingDrag.png 1,866 × 700; 225 KB