Chisels

From DT Online

Description

Chisels are mainly hand-held tools designed with an edge sharpened to cut through materials including: wood, metals, and stone.

Features and Applications

Most chisels are made from Hardened and Tempered Tool Steel and the material to be cut determines the design of the cutting edge and the angles at which they are sharpened.

Wood Chisels

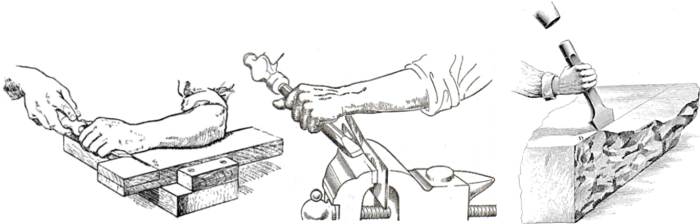

Chisels used for cutting wood are ‘sharp edge tools’ with a bevel on one side only. Different operations are required to produce the keen cutting edge required. These are:

- grinding to an angle of 20° to 25° using a Tool Grinder;

- ‘honing’ at an angle of 25° to 30° (i.e. 5° greater than the grinding angle) with a sharpening stone such as an Oilstone;

- finally, when a very keen edge is required, ‘stropping’ on a strip of leather coated with a very fine abrasive powder such as fine pumice or emery powder mixed with oil.

Safety Point! When using a Chisel, always hold the work securely using a Vice or Cramp and always have both hands behind the cutting edge (i.e. either both on the Chisel or one on the Chisel and one on the Mallet if used)

| Bevel Edge Chisel | The general purpose wood chisel available with either wood or plastics handles and the blade either fitted to it via a tang or a socket. The bevelled edges allow working within acute angles such as when cutting Dovetail Joints. They are usually Hardened and Tempered almost all the way to the handle to allow for frequent re-grinding and sharpening during their lifetime use. |  |

| Firmer Chisel | These are more robust than Bevel Edge Chisels and therefore more suitable for heavier work. |  |

| Paring Chisel | This Chisel is a longer and thinner chisel which allows greater reach and better control when using it to remove small shavings (e.g. to improve the fit of Mortise and Tenon Joints or flatten the bottom of a Housing Joint). They are never used with Mallets and are also available with a cranked handle for the most awkward to reach areas. |  |

| Registered Mortice Chisel | These are heavy duty chisels with thicker square edged blades mainly used to cut Mortises and lever out the waste as cutting proceeds. The handles often have a metal ferrule at the striking end and a leather washer between the handle and the blade to absorb shock as they are struck with a Mallet. The spurs of a Mortise Gauge are set to the width of the Mortise Chisel to be used. |  |

| Swan Neck Mortise Chisel | The cranked blade of these Mortise Chisels allows the bottom of a deep Mortise to be cleaned out by levering against the sides as shown. |  |

| Hollow Bit Mortise Chisel | Chisels used in a Mortiser are sharpened square tubes inside which an Auger Bit revolves to remove the bulk of the waste as the chisel is pressed into the work-piece. It is essentially a Broaching process. |  |

Metal Chisels

Known as Cold Chisels, these are used with a hammer to cut metal and therefore require a stronger cutting edge than for a wood chisel. They are ground to a bevel on each side forming an included angle of 60° using a Tool Grinder. The tool tip is Hardened and Tempered but the striking end is left soft but slightly chamfered to reduce the amount of ‘mushrooming’ caused by the hammer blows.

Note: They are known as Cold Chisels to differentiate them from the Blacksmiths' Hot Set which is sharpened to a narrower angle and not Hardened and Tempered because it is used only to cut through hot metal the heat from which might 'draw' the temper and soften it.

| Cold Chisel | These are most commonly used for splitting rusted-on Nuts, removing Rivet Heads or cutting away waste metal which would be difficult to get at using other tools (e.g. sheet metal can be gripped with the line to be cut close to the top of an Engineers Vice and cut with a Shearing action as the Cold Chisel is struck with a hammer along the top of the vice jaws). |  |

| Cross Cut Chisel | These are used to cut slots and grooves in metal (e.g. to cut a Keyway). |  |

Mason's Chisels

Chisels for cutting brick and stone are constructed and sharpened in much the same way as Cold Chisels. They are commonly used with a Lump Hammer to generate striking force required, and so are often available with soft plastic covers for the handles to shield the hand from injury by misplaced hammer blows.

| Bolster | These can be used as an alternative to a Brick Hammer to cut larger size blocks, bricks and stone by first scribing round then striking with a Lump Hammer. They are available in different widths (e.g. to chase out plaster for electrical conduits) and some with sharper edges (e.g. to cut through and lever-up floor boards). |  |

| Plugging Chisel | These are designed to cut or chase out the mortar from between courses of brick or stone either to drive in a wooden plug (as an alternative to a plastic wall plug) or as preparation for Re-pointing. |  |

| Scutch Comb Chisel | These have a serrated cutting edge designed as a replaceable ‘comb’. They are used for rapid removal of masonry when levelling, chiselling, channelling or shaping stone or brick. |  |