Snarling

From DT Online

Description

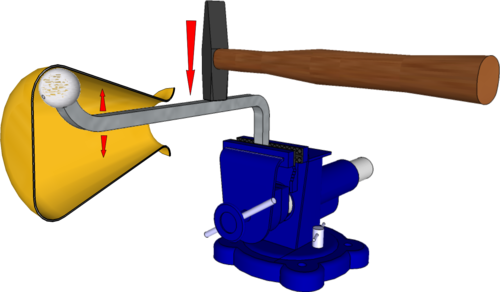

Snarling is a process used to hammer out tall Raised forms or narrow-necked objects from the inside by striking the neck of a Snarling Iron held in a vice causing it to vibrate against the inside of the vessel.

Process

A Snarling Iron is gripped firmly in a vice and the object slid over to position the job on the head. The neck is struck sharply with a hammer causing it to rebound against the inside of the object. After each blow the job is rotated to its next position and the iron struck again until the desired shape is achieved.

Snarling can be used to correct dents or imperfections in existing products or to create raised designs on them. The rounded ball end may be substituted with other shapes to vary the embossed designs.

- 12oz Hammers (0.45kg) are a good useful size for general work in Design and Technology.

- Larger 2lb hammers (1kg) are used for heavier work such as Blacksmithing for example.

- Smaller hammers (e.g. 4oz and 8oz) are suitable for jewellery work and model engineering applications.

- Brick Hammers between 1lb and 1.5lb weight (450g to 700g) are suitable for school use and are available also with a Scutch Comb Chisel at one end which can be used for shaping brick and masonry.

- A 2lb Lump Hammer (0.9kg) is a good useful size for general work in Design and Technology and home maintenance tasks.

- 2lb to 4lb Sledge Hammers (1-2kg) are a suitable size for general forge-work in Design and Technology since hammers heavier than 4lb would be difficult for students to use.

|

|

|

|

|

|

|

|

| Ball Pein Hammer |

Blacksmiths Hammers |

Brick Hammer |

Claw Hammer |

Cross Pein Hammer |

Lump (or Club) Hammer |

Pin Hammer |

Sledge Hammer |