Kerf: Difference between revisions

From DT Online

m (Added category links) |

mNo edit summary |

||

| Line 16: | Line 16: | ||

'''‘Kerfing’''' is a process whereby several parallel cuts are made close together across a board, but only part way through the thickness, to make the board easier to bend - the kerf must be on the inside of the bend such that they close up by compression. | '''‘Kerfing’''' is a process whereby several parallel cuts are made close together across a board, but only part way through the thickness, to make the board easier to bend - the kerf must be on the inside of the bend such that they close up by compression. | ||

[[Category:Secondary]] | [[Category:Secondary]] | ||

[[Category:Tools and Equipment]] | [[Category:Tools and Equipment]] | ||

[[Category:Terminology]] | [[Category:Terminology]] | ||

Revision as of 17:54, 29 April 2015

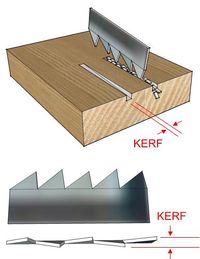

The Kerf is the small groove created as a saw cuts through materials and provides clearance for the rest of the blade to stop it binding.

On woodsaws, the width of the kerf is usually detemined by the amount of set which is the process of angling alternate saw teeth to either side of the blade such that the cut is wider than the blade itself. Saw teeth are usually bent outwards to about 1/4 to 1/3 of the blade thickness each side to create the set.

Some fine tooth blades such as for a Junior Hacksaw, are set by producing a wavy edge along the blade. Modern Circular Saw blades have tungsten carbide tips which are wider than the steel blade they are brazed on to and this creates the set.

Note: The width of kerf has to be allowed for when cutting materials to length or width - always cut on the waste side of a line.

‘Kerfing’ is a process whereby several parallel cuts are made close together across a board, but only part way through the thickness, to make the board easier to bend - the kerf must be on the inside of the bend such that they close up by compression.