Soldering Irons: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| Line 1: | Line 1: | ||

[[File:CopperBitSolderingIrons.png|Soldering | [[File:CopperBitSolderingIrons.png|Soldering Irons|300px|right]] | ||

=====Description===== | =====Description===== | ||

Traditional [https://en.wikipedia.org/wiki/Soldering_iron '''Soldering | Traditional [https://en.wikipedia.org/wiki/Soldering_iron '''Soldering Irons'''] comprise a [https://en.wikipedia.org/wiki/Copper '''Copper'''] head attached to a wooden handle. The head can be pointed, have a chisel edge or be set at right angle to the shaft to form a 'hatchet' iron depending on the application. | ||

=====Features and Applications===== | =====Features and Applications===== | ||

''' | '''Soldering Irons''' are easily self-made from a piece of 20mm or 25mm square [https://en.wikipedia.org/wiki/Copper '''Copper'''] stock, attached to a file-type handle via a length of 6mm - 8mm steel bar. The 'irons' are heated with a gas torch and '''Copper''' is chosen because of its ability to store and retain the heat then transfer it to the workpiece. | ||

Gas heated irons can supply much more heat than '''[[Electric Soldering Irons]]''' and can be used in combination with a gas torch to supply additional heat. They are therefore suitable when large '''[[:Category:Beaten Metalwork|Beaten Metalwork]]''' items, made of conductive metals such as copper or brass, have to be soldered for example. A further advantage for this type of work is that they can be used with liquid active fluxes such as '''Bakers Fluid'''. | Gas heated 'irons' can supply much more heat than '''[[Electric Soldering Irons]]''' and can be used in combination with a gas torch to supply additional heat. They are therefore suitable when large '''[[:Category:Beaten Metalwork|Beaten Metalwork]]''' items, made of conductive metals such as copper or brass, have to be soldered for example. A further advantage for this type of work is that they can be used with liquid active fluxes such as '''Bakers Fluid'''. | ||

Revision as of 16:34, 18 May 2017

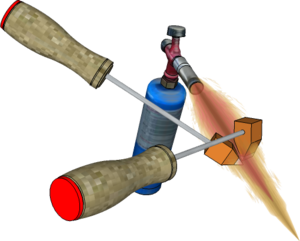

Description

Traditional Soldering Irons comprise a Copper head attached to a wooden handle. The head can be pointed, have a chisel edge or be set at right angle to the shaft to form a 'hatchet' iron depending on the application.

Features and Applications

Soldering Irons are easily self-made from a piece of 20mm or 25mm square Copper stock, attached to a file-type handle via a length of 6mm - 8mm steel bar. The 'irons' are heated with a gas torch and Copper is chosen because of its ability to store and retain the heat then transfer it to the workpiece.

Gas heated 'irons' can supply much more heat than Electric Soldering Irons and can be used in combination with a gas torch to supply additional heat. They are therefore suitable when large Beaten Metalwork items, made of conductive metals such as copper or brass, have to be soldered for example. A further advantage for this type of work is that they can be used with liquid active fluxes such as Bakers Fluid.

Gas heated portable 'irons' are also available commercially. These are used by contractors engaged in the installation of Copper guttering and Copper or Lead sheathed roofs or 'flashing' for example. Such work, undertaken outdoors, and with large sheets of conductive metal, would be difficult or impossible with even the largest Electric Soldering Irons - especially in cold and windy conditions.

Maintenance

The Copper tip, or ‘bit‘, of all soldering irons must be kept clean and coated with a thin layer of solder - a process known as ‘Tinning’. This is achieved by heating the 'iron', thoroughly cleaning the tip with a file and Emery Cloth, dipping it into Flux, then melting on to it a small amount of solder.

|

|

|

|

|

|

|

|

|

| Soldering Iron Station |

Multicore Solder |

LED Magnifier with Clamps and Soldering Stand |

Soldering Mat |

Soldering Flux |

Soft Solder |

Bakers Soldering Fluid |

Solder Flux Brushes |

Gas Soldering & Brazing Torch |