Bridle Joint: Difference between revisions

From DT Online

m Added Dovetail Bridle |

mNo edit summary |

||

| Line 14: | Line 14: | ||

<div style="clear: both;"></div> | <div style="clear: both;"></div> | ||

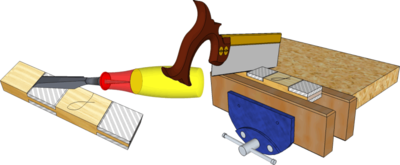

=====Marking Out===== | =====Marking Out===== | ||

[[File:BridleJointMarkingOut.png|750px]] | [[File:BridleJointMarkingOut.png|750px|center]] | ||

* The joining pieces are prepared as normal and marked with '''[[Face Side and Face Edge]]''' marks. | * The joining pieces are prepared as normal and marked with '''[[Face Side and Face Edge]]''' marks. | ||

* The joint positions are marked out using a Pencil and '''[[Try Square]]'''. | * The joint positions are marked out using a Pencil and '''[[Try Square]]'''. | ||

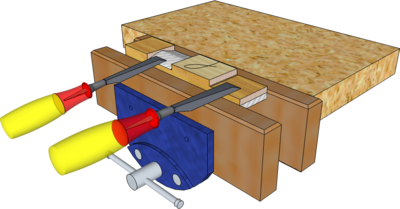

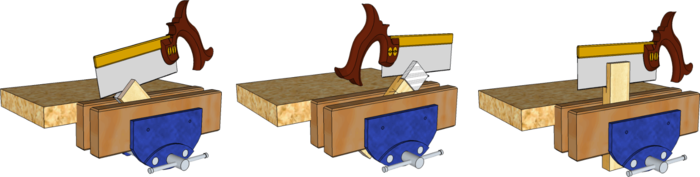

| Line 47: | Line 47: | ||

* Reverse the angle and saw position carefully to saw along the gauge lines along the other side and once again across the end. | * Reverse the angle and saw position carefully to saw along the gauge lines along the other side and once again across the end. | ||

* Arrange the work vertically in the '''[[Carpenters Vice]]''' and continue the cut down to the ''shoulders'', using the previous angled cuts to guide the blade - and always with the waste on the ''blind side'' of the saw. | * Arrange the work vertically in the '''[[Carpenters Vice]]''' and continue the cut down to the ''shoulders'', using the previous angled cuts to guide the blade - and always with the waste on the ''blind side'' of the saw. | ||

[[File:HalvingJointSawingCheek.png|700px| | [[File:HalvingJointSawingCheek.png|700px|center]] | ||

---- | ---- | ||

<span style="color: green">'''Note:''' | <span style="color: green">'''Note:''' | ||

| Line 84: | Line 84: | ||

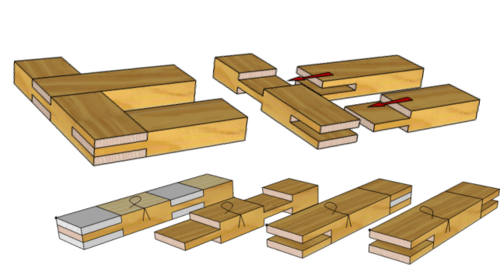

=====Types of Bridle Joint===== | =====Types of Bridle Joint===== | ||

'''Bridle Joints''' can be used as a general, joining method for any ''corner angle'' or ''Tee'' type of frame joint configuration. | '''Bridle Joints''' can be used as a general, joining method for any ''corner angle'' or ''Tee'' type of frame joint configuration. | ||

[[File: BridleJointVariations.png|750px| | [[File: BridleJointVariations.png|750px|center]] | ||

<div style="clear: both;"></div> | <div style="clear: both;"></div> | ||

* '''Corner Bridle''' joints can be used as a simpler substitute for a '''[[Mortise and Tenon Joint|Haunched Mortise and Tenon Joint]]''', especially where the frame is to be skinned or covered ''(e.g. frames for loose, padded chair seats)''. | * '''Corner Bridle''' joints can be used as a simpler substitute for a '''[[Mortise and Tenon Joint|Haunched Mortise and Tenon Joint]]''', especially where the frame is to be skinned or covered ''(e.g. frames for loose, padded chair seats)''. | ||

Revision as of 10:07, 19 February 2016

Bridle Joints are a general framing joint. They have twice the gluing area of a Halving Joint and are therefore stronger.

They are similar to a Mortise and Tenon Joint except the tenon or pin and slot or socket extend across the full width of the timber. The pins and sockets are normally one third the thickness of the timber.

There are two configurations of a Bridle Joint : the Corner Bridle and the Tee Bridle. The Corner Bridle can have one or both of its faces mitred and the Tee Bridle can be stopped if it is necessary to hide the End Grain.

Marking Out

- The joining pieces are prepared as normal and marked with Face Side and Face Edge marks.

- The joint positions are marked out using a Pencil and Try Square.

- The pins of a Mortise Gauge are set to one third the thickness of timber and the Gauge Stock adjusted to scribe the double lines down the centre of the timber thickness.

- A Marking Knife is used with a Try Square to scribe an incised line along where the shoulders are to be cut.

Sawing the Shoulders

- Pare with a Chisel to cut a shallow 'Vee' groove across the line of the shoulders to guide the saw.

- If needed, on wider boards for example, a piece of scrap timber can be clamped along the line to be cut to guide the saw (see Corner Lap Joint).

- Saw all shoulders down to the gauge lines using a Tenon Saw.

Note: Turn the work piece round in the vice to ensure it is the waste which is always on the 'blind side' of the saw.

Removing Waste from Tee Bridle 'Pins'

- Hold the work firmly in a Carpenters Vice, grip a chisel with one hand and taking a Mallet in the other hand, gently tap in an upwards direction to remove the waste to half way across.

- Reverse the work-piece in the Carpenters Vice and repeat from the other side to complete waste removal.

- To complete both pins and tenons of all Bridle Joints, some careful Paring with a sharp Chisel can be used to ensure all sides of the joint are levelled down to the gauge lines.

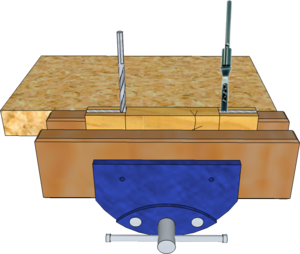

Cutting Corner Bridle 'Tenons'

- The sides (or cheeks) of the tenons of a Corner Bridle Joint can be cut with a Tenon Saw.

- Arrange the work-piece in the Carpenters Vice at an angle with the waste on the blind side of the saw.

- Using a Tenon Saw carefully saw along the gauge lines along the side and across the end.

- Reverse the angle and saw position carefully to saw along the gauge lines along the other side and once again across the end.

- Arrange the work vertically in the Carpenters Vice and continue the cut down to the shoulders, using the previous angled cuts to guide the blade - and always with the waste on the blind side of the saw.

Note: The sides (or cheeks) of Corner Bridle Joint tenons can also be cut down to the shoulders using a Bandsaw.

Cutting Bridle Joint 'Sockets'

Sockets are required for both Tee Bridle Joints and Corner Bridle Joints and there are several ways to cut them:

- Drilling and Sawing

- Hollow Chisel Mortiser

- Cut down the end of the socket using a Hollow Chisel Mortiser of a size equal to the width of the socket and saw down to it.

- Or, with repeated cuts of the Mortiser work along the entire socket to remove all waste.

- Using a Mortise Chisel

- The waste from the socket can also be removed using the same technique as used for cutting a Mortise in a Mortise and Tenon Joint.

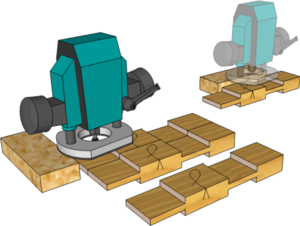

Using a Router

With the work-piece securely held, a Router can be used to cut Bridle Joint tenons or pins from the beginning. If required, additional pieces of equal thickness timber can be used to balance it and guides, Jigs or fences set up to obviate the need for some marking out.

It is possible also to clamp several work-pieces together to cut multiple tenons or pins in a single cut (but take care to ensure the depth of the 'shoulder' and the thickness of the 'cheek' is always gauged from the Face Side)

Safety Point! All high-speed woodcutting machinery is dangerous. Routers and Bandsaws must only be used by trained adults or trainees under direct supervision by specifically trained staff.

Types of Bridle Joint

Bridle Joints can be used as a general, joining method for any corner angle or Tee type of frame joint configuration.

- Corner Bridle joints can be used as a simpler substitute for a Haunched Mortise and Tenon Joint, especially where the frame is to be skinned or covered (e.g. frames for loose, padded chair seats).

- Tee Bridle joints can be used as a simpler alternative to a Mortise and Tenon Joint but where a joint stronger than a Halving Joint is required.

- Mitred Corner Bridle joints are used where a joint stronger than a Mitred Halving Joint is required and where a moulding, groove or rebate runs round the corner (e.g. mirror frames). Either one or both sides of the socket may be mitred as required.

- Dovetailed Bridle joints can be used where there is some tendency for the joint to be pulled apart in one direction.