Hollowing: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| Line 47: | Line 47: | ||

Once a satisfactory hollowed form has been achieved, it can be trued and the metal '''[[Crystalline_Structures#Work_Hardening|Work Hardened]]''' by a process known as [https://en.wikipedia.org/wiki/Planishing '''Planishing''']. It is important that the metal is thoroughly cleaned before '''[[Planishing]]''' ''(e.g. by '''[[Pickling]]''' and/or scouring)'' to avoid any grit, oxides or other contaminants being hammered into the surface. | |||

Revision as of 08:42, 5 July 2017

Description

Hollowing, when used to describe a process in Beaten Metalwork (e.g. Coppersmithing or Silversmithing), is the initial operation used to transform a flat sheet of Annealed metal into a shallow bowl form.

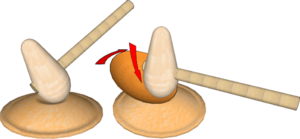

Hollowing with a Sandbag and Bossing Mallet

The established technique of Hollowing a simple bowl is first to create a hollow impression into a Sandbag using a Bossing Mallet. The flat disc of metal is then held at an angle to the hollow and beaten into it using the larger diameter end of a Bossing Mallet.

The mallet is consistently beaten down on to the same place on the Sandbag as the metal is turned under it. As the process continues, the metal is passed further under the mallet such that it is struck in series of decreasing circles starting at the outside and working towards the centre.

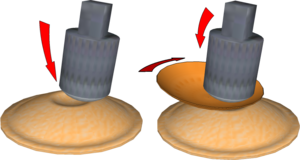

Hollowing with a Sandbag and Planishing Stake

Some Silversmiths prefer to use a Planishing Stake instead of a Bossing Mallet. Although not as comfortable to hold as mallet, the Stake has good weight and imparts a curve on the metal similar to the curve of the stake over which the hollowed bowl will be trued and finished by Planishing.

The work should rotate and the strikes progress from outside to centre as when using a Bossing Mallet

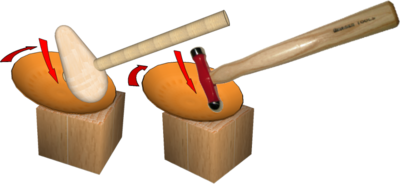

Using a Hollowing Block

An alternative to supporting the work on a hollowed Sandbag is to use a block of wood which has been suitably hollowed at one end - known as a Hollowing Block. This technique is particularly useful for smaller diameter or deeper forms.

Dependant on the size of product being made, either end of the Bossing Mallet may be used. Alternatively, a Blocking Hammer can be used to provide a firmer strike.

The work should rotate and the strikes progress from outside to centre as with other Hollowing techniques.

Truing the Hollowed Form

Following an initial Hollowing using either Sandbag or Hollowing Block, the second operation is to true the roughed out form by beating it over a Planishing Stake using the flat-face of a Rawhide Mallet.

As with the initial Hollowing, the mallet strikes the Stake in the same place each time as the metal is rotated and passed under it to cause strikes to be in decreasing circles from outer rim to centre.

Once a satisfactory hollowed form has been achieved, it can be trued and the metal Work Hardened by a process known as Planishing. It is important that the metal is thoroughly cleaned before Planishing (e.g. by Pickling and/or scouring) to avoid any grit, oxides or other contaminants being hammered into the surface.

|

|

|

|

|

|

|

| Jewellers Leather Sandbag |

Bossing Mallet |

Rawhide Mallet |

Jewellers Hammers |

Repoussé and Chasing Punches |

Panel Beating Tools Set |

Doming Block and Punches |