Planishing

From DT Online

Description

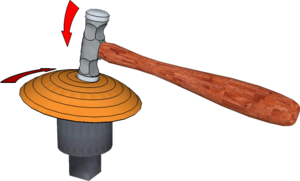

Planishing,is a process used to true and smooth out the surface of Beaten Metalwork items formed previously by Hollowing, Seaming or Raising for example. It is important that the metal is thoroughly cleaned before Planishing (e.g. by Pickling and/or scouring) to avoid any grit, oxides or other contaminants to be hammered into the surface..

The process involves striking the metal surface with a highly polished Planishing or Collet Hammer whilst it is held firmly against the surface of a highly polished Planishing Stake. This imparts a polish on to the beaten metal surface and also Work Hardens the previously Annealed sheet. Hammer blows should overlap and be directed always at the same place on the Stake as the metal is moved round underneath. It can be helpful to draw pencil guidelines on the metal surface to ensure even and consistent working.

For more industrial scale operations, foot-operated pneumatically powered Planishing Hammers are available and Panel Beaters may make use of an English Wheel

when forming and polishing aluminium car body parts for example.

Features and Applications

Planishing if done correctly will impart a finish to the metal surface which, after final Buffing and polishing, causes the light to 'dance' over the metal surface. It is NOT the purpose of Planishing to leave the surface covered with deep hammer marks as seen on objects traded as 'hammered copperwork' for example.

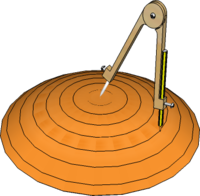

Planishing a Bowl form

Planishing Hammers usually have one flat face and one slightly domed face. A general rule when Planishing to to choose round when Planishing a flat surface and flat when working on a domed surface.

In the case of a shallow bowl, for example, this is achieved by striking the metal with the flat face of the hammer over a domed Planishing Stake.

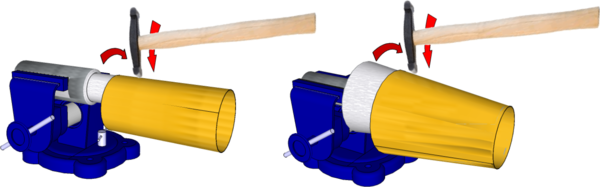

Planishing Cylinders and Cones

The surface of either a Cylindrical or Conical form is straight along its axis but curved around the circumference, so neither the flat face nor the domed face of a Planishing Hammer would be suitable. Objects with a largely cylindrical and conical form should therefore be Planished against a cylindrical and conical Stake with a Collet Hammer held as shown, which itself has two slightly cylindrically curved faces.

- 12oz Hammers (0.45kg) are a good useful size for general work in Design and Technology.

- Larger 2lb hammers (1kg) are used for heavier work such as Blacksmithing for example.

- Smaller hammers (e.g. 4oz and 8oz) are suitable for jewellery work and model engineering applications.

- Brick Hammers between 1lb and 1.5lb weight (450g to 700g) are suitable for school use and are available also with a Scutch Comb Chisel at one end which can be used for shaping brick and masonry.

- A 2lb Lump Hammer (0.9kg) is a good useful size for general work in Design and Technology and home maintenance tasks.

- 2lb to 4lb Sledge Hammers (1-2kg) are a suitable size for general forge-work in Design and Technology since hammers heavier than 4lb would be difficult for students to use.

|

|

|

|

|

|

|

|

| Ball Pein Hammer |

Blacksmiths Hammers |

Brick Hammer |

Claw Hammer |

Cross Pein Hammer |

Lump (or Club) Hammer |

Pin Hammer |

Sledge Hammer |