Drilling and Boring: Difference between revisions

From DT Online

Added category link |

Added Images and text |

||

| Line 1: | Line 1: | ||

[https://en.wikipedia.org/wiki/Drilling '''Drilling'''] is most often the process of revolving a tool bit at a suitable speed to cut a hole into or through a piece of material - although the reverse can be true ''(e.g. when drilling on a '''[[Centre Lathe]]''' the work is usually held with a '''Chuck''' or '''Faceplate''' and revolved while the drill bit is held stationary in a '''Tailstock''' '''Toolpost''')''. | |||

[https://en.wikipedia.org/wiki/Boring_%28manufacturing%29 '''Boring'''] is used to enlarge an existing hole - one which often, but not always, has been drilled previously. This done usually with a single point tool and, as with drilling, either the tool or the workpiece can revolve depending on the operation in hand. | |||

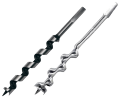

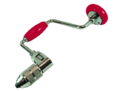

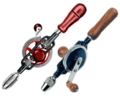

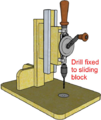

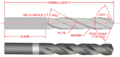

[https://en.wikipedia.org/wiki/Drill_bit '''Drill Bits'''] and [https://en.wikipedia.org/wiki/Boring_%28manufacturing%29 '''Boring Tools'''] are designed to be gripped using the wide variety of devices used to hold them. Most commonly they have a [https://en.wikipedia.org/wiki/Drill_bit_shank#Straight_shank '''Parallel Shank'''] which is gripped by most '''[[Hand Drills]]''' and '''[[Portable Electric Drills|Portable Power Drills]]'''; traditional [https://en.wikipedia.org/wiki/Drill_bit_shank#Brace_shank '''Square Tapered Shanks'''] were held in a '''[[Carpenter's Brace]]''' and [https://en.wikipedia.org/wiki/Drill_bit_shank#Morse_taper_shank '''Morse Taper Shanks'''] are used in many '''[[:Category:Machine Tools|Machine Tools]]'''. [https://en.wikipedia.org/wiki/Drill_bit_shank#Hex_shank '''Hexagonal Shanks'''] can be used in ordinary [https://en.wikipedia.org/wiki/Chuck_%28engineering%29 '''3-jaw chucks'''] when extra [https://en.wikipedia.org/wiki/Torque '''Torque'''] is required and many '''[[Portable Electric Drills|Hammer Drills]]''' require bits with [https://en.wikipedia.org/wiki/Drill_bit_shank#SDS_shank '''SDS Shanks''']. | |||

[[Category:Tools and Equipment]] | [[Category:Tools and Equipment]] | ||

Revision as of 22:47, 26 October 2015

Drilling is most often the process of revolving a tool bit at a suitable speed to cut a hole into or through a piece of material - although the reverse can be true (e.g. when drilling on a Centre Lathe the work is usually held with a Chuck or Faceplate and revolved while the drill bit is held stationary in a Tailstock Toolpost).

Boring is used to enlarge an existing hole - one which often, but not always, has been drilled previously. This done usually with a single point tool and, as with drilling, either the tool or the workpiece can revolve depending on the operation in hand.

Drill Bits and Boring Tools are designed to be gripped using the wide variety of devices used to hold them. Most commonly they have a Parallel Shank which is gripped by most Hand Drills and Portable Power Drills; traditional Square Tapered Shanks were held in a Carpenter's Brace and Morse Taper Shanks are used in many Machine Tools. Hexagonal Shanks can be used in ordinary 3-jaw chucks when extra Torque is required and many Hammer Drills require bits with SDS Shanks.

Pages in category "Drilling and Boring"

The following 26 pages are in this category, out of 26 total.

R

Media in category "Drilling and Boring"

The following 33 files are in this category, out of 33 total.

-

AugerBits.png 663 × 555; 42 KB

-

AwlBradawl.png 575 × 397; 37 KB

-

BenchDrills.png 800 × 286; 54 KB

-

CarpentersBrace.png 558 × 422; 29 KB

-

CentreBit.png 369 × 396; 21 KB

-

CentreDotPunching.png 227 × 227; 5 KB

-

CentreDrill.png 265 × 236; 11 KB

-

CoreDrill.png 599 × 472; 47 KB

-

CskBits.png 404 × 394; 28 KB

-

DowelBits.png 506 × 259; 21 KB

-

DrillHandle.png 488 × 422; 27 KB

-

ExpansiveBit.png 383 × 402; 16 KB

-

FlatSpadeBit.png 340 × 410; 10 KB

-

ForstenerBit.png 502 × 600; 62 KB

-

GimletSnailBit.png 547 × 560; 47 KB

-

GlassCeramicDrills.png 620 × 482; 69 KB

-

HammerDrill.png 500 × 350; 21 KB

-

HandDrills.png 622 × 510; 70 KB

-

HanddrillStand.png 479 × 569; 247 KB

-

Holesaw.png 576 × 386; 55 KB

-

HoleSawSet.png 335 × 305; 38 KB

-

MasonryBits.png 495 × 404; 24 KB

-

MiniHandDrills.png 636 × 566; 205 KB

-

PedestalDrill.png 800 × 800; 164 KB

-

PlugCutter.png 381 × 389; 27 KB

-

PumpDrill.png 500 × 375; 28 KB

-

Reamers.png 1,416 × 473; 101 KB

-

SpotFaceCutters.png 550 × 463; 34 KB

-

StepDrillConeCut.png 479 × 397; 39 KB

-

TrepanningTankCutter.png 610 × 591; 49 KB

-

TwistDrill.png 1,000 × 471; 78 KB

-

TwistDrills.png 515 × 323; 29 KB

-

TwistDrillSet.png 610 × 734; 90 KB