Sinking Block

From DT Online

Description

Sinking is a process used to create flat, shallow tray shapes (i.e. Flatware) by beating an Annealed sheet metal shape into a recess formed in the end grain of a suitable block of close-grained Hardwood known as a Sinking Block.

Features and Uses

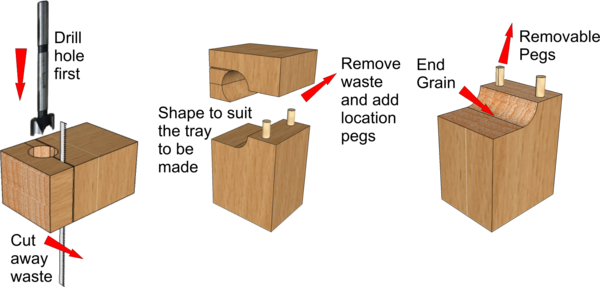

Sinking Blocks are usually self-made as required with removable pegs to maintain a constant width of rim where needed. A suitable manufacturing procedure is shown below:

- first, a block of close-grained Hardwood is drilled through towards one end with a drill diameter twice the required recess depth (e.g. using Forstener Bits);

- then the waste is removed to reveal the required 'step'.

- Removable pegs are added to complete the block ready for Sinking.

- 12oz Hammers (0.45kg) are a good useful size for general work in Design and Technology.

- Larger 2lb hammers (1kg) are used for heavier work such as Blacksmithing for example.

- Smaller hammers (e.g. 4oz and 8oz) are suitable for jewellery work and model engineering applications.

- Brick Hammers between 1lb and 1.5lb weight (450g to 700g) are suitable for school use and are available also with a Scutch Comb Chisel at one end which can be used for shaping brick and masonry.

- A 2lb Lump Hammer (0.9kg) is a good useful size for general work in Design and Technology and home maintenance tasks.

- 2lb to 4lb Sledge Hammers (1-2kg) are a suitable size for general forge-work in Design and Technology since hammers heavier than 4lb would be difficult for students to use.

|

|

|

|

|

|

|

|

| Ball Pein Hammer |

Blacksmiths Hammers |

Brick Hammer |

Claw Hammer |

Cross Pein Hammer |

Lump (or Club) Hammer |

Pin Hammer |

Sledge Hammer |